Seldom in one’s career does an engineer have the opportunity to design a structure described as “dramatic.” This past year, I received that exact opportunity in the form of a pedestrian bridge.

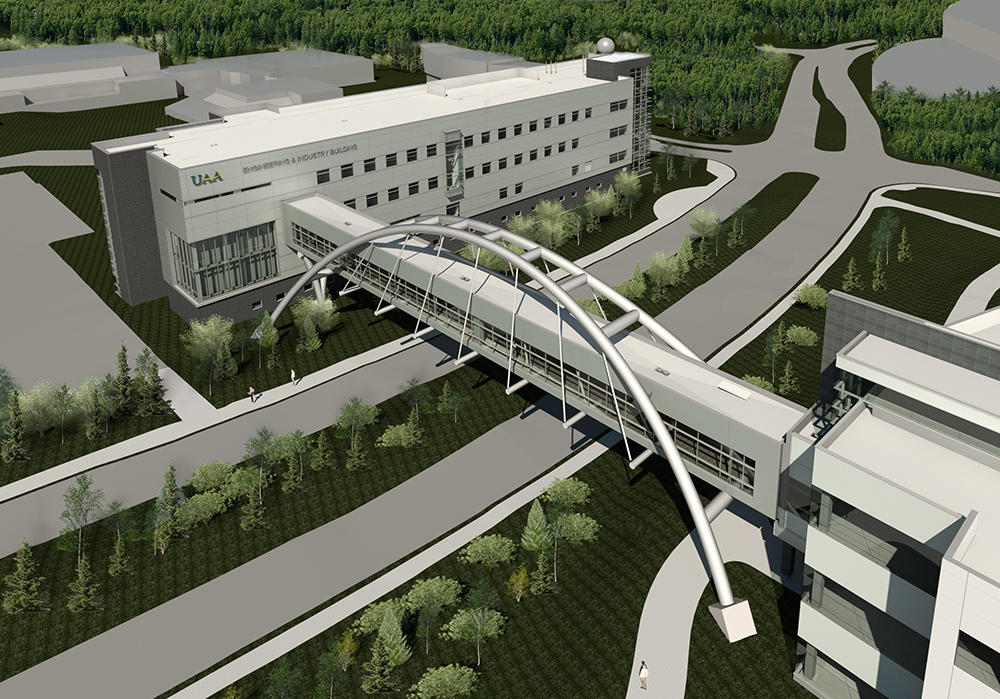

As the design phase of the new $50 million Engineering and Industry Building for the University of Alaska (UAA) wrapped up, the University approached the design team, led by Livingston Slone, with an offer: design a pedestrian bridge between two buildings over a busy 4-lane roadway. The caveats: it must clear-span the road, and it can’t look “ordinary.” Attempting not to drool from excitement, our team naturally accepted the challenge. Next, we were tasked to prepare several concept options. The architects deferred to Courtney Willoughby and me, the structural engineers on the team, to employ our own creativity and take the lead in the designs with moderate architectural input.

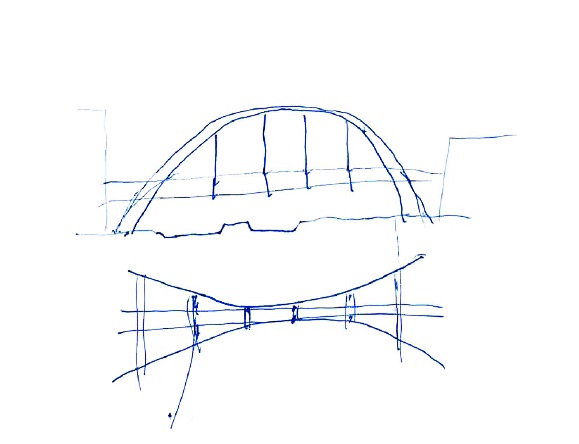

At our first meeting, as the team threw out ideas and concerns, I listened to the debates while dreamily sketching up an idea on a piece of company notepaper. It depicted two arches bent in on themselves with a corridor passing between them. A few months later, as we presented several designs that ranged from “pedestrian” (pun intended) to “are-you-serious?” the arch concept was the clear choice of the University, and we were directed to proceed with its design.

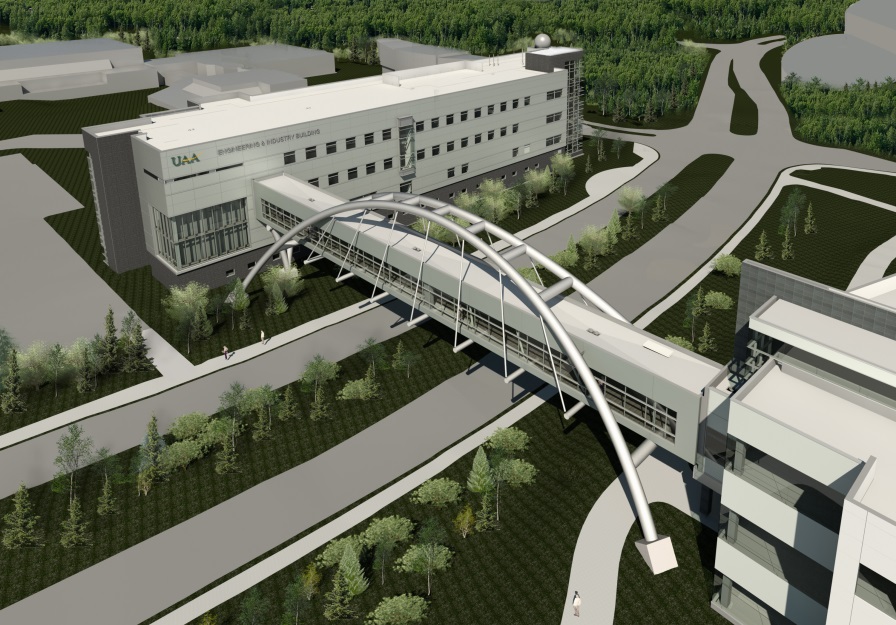

The bridge spans 224 feet between two buildings on the University of Alaska campus — the Health Sciences Building (School of Nursing) and the under-construction Engineering and Industry Building (School of Engineering). To tip our own hats, Reid Middleton also provided structural design for both buildings.

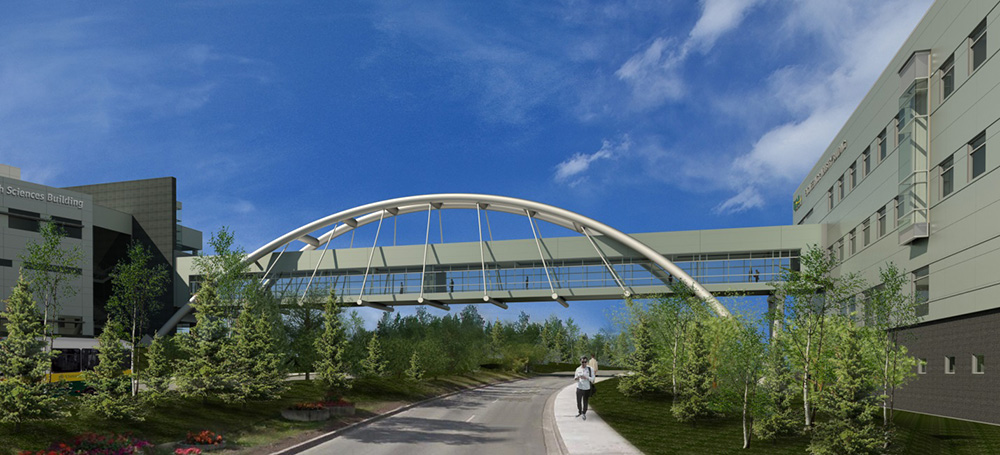

The apex of the arch rises 60 feet above the roadway, with aesthetic support struts that fan out and carry the 15-foot-wide corridor. The corridor employs floor-to-ceiling glass walls along both sides, allowing for maximum transparency and views of both the campus and the mountains. The bridge is composed of two primary elements: an arch superstructure and an enclosed conditioned space corridor. Each arch is made from 36-inch-diameter steel pipe with half-inch-thick walls.

The arches are tied together with crossbeams that are also 36-inch-diameter pipe. Each arch base is attached to aesthetic above-grade sloped concrete piers that match the angle of the arch pipes above the concrete with twenty four 1-1/4-inch-diameter anchor rods. Massive concrete footings resist the enormous thrust imposed by the arch system.

One of the coolest parts of the design process involved an intense Saturday morning meeting with Reid Middleton, the erector, the fabricator, the contractor, and the architect. We realized that initial collaboration was necessary in order to complete our design. Fabrication tolerances and restrictions dictated splice locations. Erection shoring and sequencing dictated types of connections and span limitations. Installation during a two week road closure over Christmas break dictated in-place connections versus off-site field connections. The time of year dictated maximum permissible member or shop-welded assembly sizes that must fit through a railroad tunnel. All of these conditions were incorporated into our final

design. Lacking input from any one of these key players could lead to serious problems during construction.

The bridge opens concurrently with the Engineering building in August 2015. It will be the only tie over a busy thoroughfare that bisects an ever-expanding campus. The bridge will be one of the most visible and iconic structures on the campus, inviting those who pass under its arches to enter — a gateway to the University of Alaska Anchorage.

Design Team

Architect: Livingston Slone, Inc.

Civil Engineer: Dowl HKM

Landscape Designer: Corvus Design

Structural Engineer: Reid Middleton

Mechanical Engineer: AMC Engineer

Electrical Engineer: AMC Engineers

Contractor: Neeser Construction