Photo courtesy Osman Akan archive.

As a structural engineer, my favorite projects are those that have creative or unique aspects that are outside of the box: projects for which our handy-dandy catalogs of standard details are thrown right out the window. I got my wish (and then some) when we were asked to engineer a $500,000 sculpture at the new Alaska State Crime Lab.

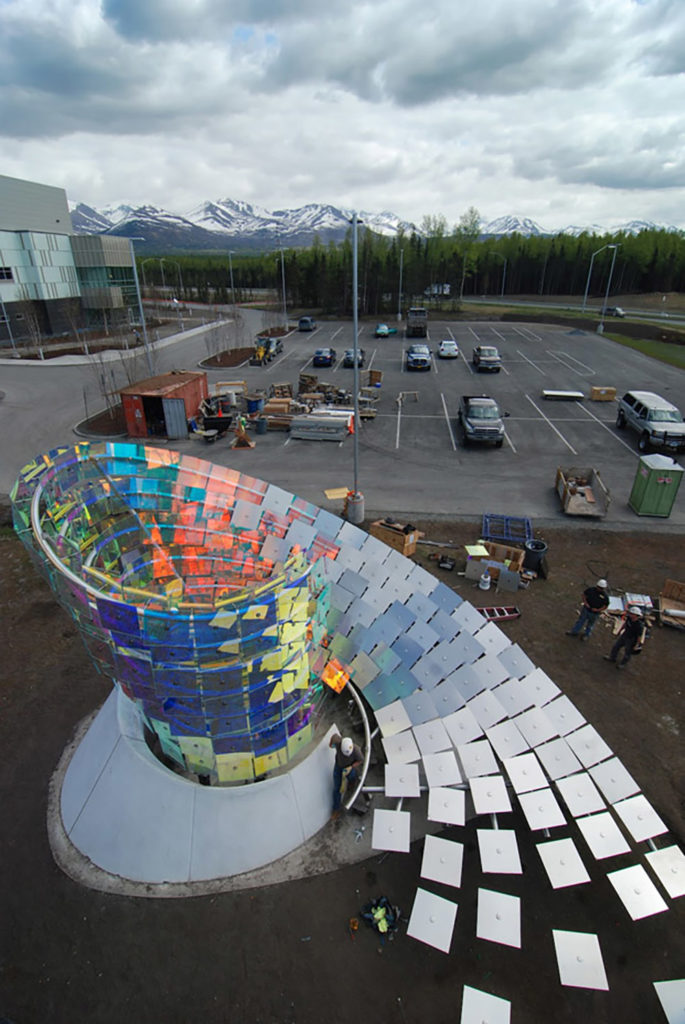

The sculpture, called “Fragmenta,” is surprisingly difficult to describe with hand gestures and even harder to convey through words. It has garnered many nicknames, including “The Whirly Whirl,” “Washer,” “Toilet Bowl,” and the more pedestrian “Outside Thingy.” It has a spiral frame of stainless steel pipe, about 20-feet high and 30-feet in diameter, covered in a skin of 2-foot by 2-foot panels of dichromatic glass and metal.

It is shaped like a roll of ribbon stood on end that has unraveled, with the unraveled end lying flat on the ground. It is the artist’s expression of taking forensic data and “unraveling” information coded within. The dichromatic glass changes color depending on your viewing angle, and the effect is a dazzling rainbow of color that turns heads of all passersby.

Working directly with an artist was a unique experience. I appreciated his talent, but right off the bat it was obvious that concessions were required. He wanted a light-framed, delicate skeleton of steel. But, we were locating the sculpture outside in Alaska, where snow can accumulate on the panels several feet deep, and wind from an adjacent mountain pass often buffets the site with Category 3 hurricane speeds. That meant the skeleton of the sculpture needed to resist all these forces while deflecting as little as possible so the panels didn’t bump into each other and break. Yet, it needed to reflect the original vision as best as possible so it looked like a work of art and not a structure. Hence, the structural challenge.

We developed a rigid framework of 4-inch diameter stainless steel pipe running radially and longitudinally, almost spiderweb-like. Several anchors welded to steel pipe piles 15-feet deep were concealed by a large, attractive perimeter wall of white concrete, creating the appearance of a large pedestal. We used a 3-D finite element modeling program called SAP 2000 to determine the loads, stresses, and deflections on the frame. It was instrumental in coming up with an efficient system.

Design coordination with the artist took place several times a week and was done almost entirely via Skype, since he was in New York, and we were in Anchorage. I cannot imagine having worked on something like this without visual communication. We used our screens, we used marker boards, we used lots of gesturing, and sometimes we argued, i.e., “Yes, you NEED that pipe since there is gravity over there, too….”

The end design was acceptable to both engineer and artist. The fabrication of the frame went well. It was shipped up to Alaska in three pieces and spliced together in place, and the panels were then attached on site and fitted piece by piece by the artist. The result was a stunningly beautiful sculpture and a unique design experience few structural engineers have the opportunity to enjoy in their career.