Since I started my career in 2005, there has been talk of a new approach to mass timber construction known as CLT (cross laminated timber). Cross Laminated Timber has been around in Europe since the early 2000’s. European designers have built single-family homes, multi-family residential buildings, and even office buildings out of CLT. CLT allows wood buildings to reach higher than they ever have in the past. In Australia, there is a 10-story building constructed out of CLT. Right across the border to the North of us, the University of British Columbia is constructing an 18-story-tall structure that is constructed with CLT floors and will be the tallest wood-framed building in the world. This is unprecedented for wood, and raises many questions about the future. But before that, a simpler question…

What is CLT, you ask?

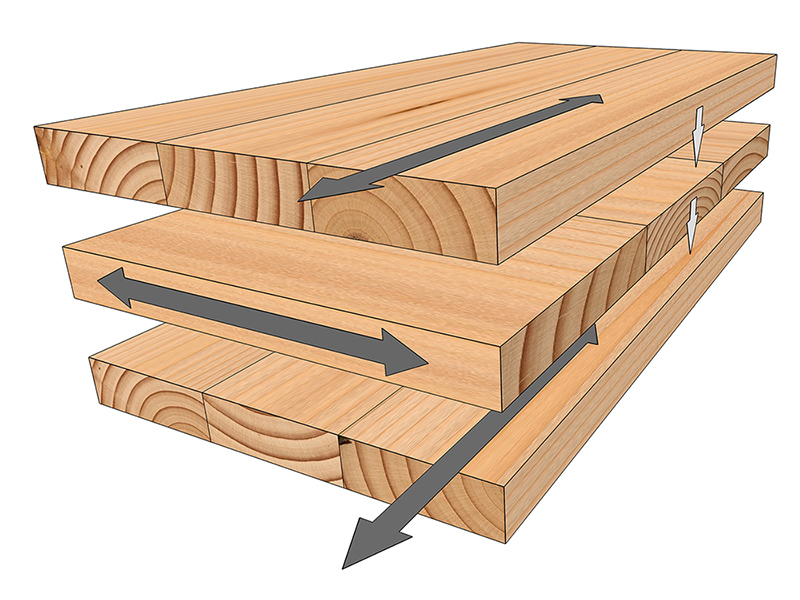

CLT consists of cross-laminated timber panels that are fabricated in a timber plant. Think of the way that plywood panels are made up of thin layers of wood, then imagine that those layers are not thin wood, but are 2x lumber. Panels can vary in dimensions and are limited mainly by transportation requirements. CLT panels are made from 2×4 or 2×6 lumber that is glued together in alternating directions, similar to Jenga pieces. If you are familiar with glulam beams, the general process is probably sounding familiar. The layers of 2x’s are stacked together orthogonally, glued and pressed, and then are planed out and finished. CLT panels are typically made of an odd number of layers; 3, 5, 7, 9, etc. Windows, doors, and MEP systems can be precut into the panels at the fabrication plant. These panels can be used for floors, roofs, walls, and as part of the lateral diaphragm and shear walls system.

CLT can be used in place of I-joists and usual stud bearing walls in typical wood-framed buildings. Depending on the thickness of the panels, spans can reach farther than typical joist framing and, because the panels have shear values, plywood doesn’t need to be installed on top of the panels. Floor and roof panels are supported by beams and or bearing walls. Drywall can be installed onto the panels to give a typical finish, or the panels can be left as-is for an aesthetically-pleasing natural wood look. CLT buildings are lighter than buildings constructed out of concrete or masonry. Lighter building require lighter foundations, which may result in cost savings, particularly for sites with difficult soils.

Because the panels are fabricated offsite, construction can be relatively quick onsite. When the panels arrive, they are lifted off the truck and placed with a crane. Then the panels are screwed into place. This gives wood construction some of the same schedule benefits that are traditionally enjoyed by structural steel.

Code recognition is critical.

CLT has been an option in the U.S. for years, however, until the 2015 International Building Code, it was not recognized by the building code and would have needed to be permitted as a specialized design alternate, adding time and uncertainty to the permitting process. Alternate materials require a discussion with the building officials on a case-by-case basis, and are subject to the judgement of the building official for approval. There is also a limited number of suppliers that currently make CLT panels in North America. This can create a “chicken and the egg” issue for supply and demand. Some buildings in North America have gone as far as to have the panels shipped from Europe. However, things are changing and there are now several companies in the Northwest that are producing CLT.

The latest codes have a growing breadth of resources for CLT design. Cross-laminated timber has also been added as a structural material in IBC Chapter 23 and the wood design standard, the NDS, has added a chapter on CLT design, including discussion of dowel-type fasteners into CLT and calculations for fire resistance. Another major wood standards organization, the APA, has also created a standard for performance-rated cross-laminated timber.

Sustainable and energy efficient.

Wood is a great sustainable building material. Carbon dioxide is absorbed and stored in trees. Wood products continue to store that carbon dioxide for their entire life cycle. Wood is also a great renewable building material. The lumber for CLT can be cut from smaller trees from forests that are certified as being sustainably managed. Anyone living in the Northwest and Alaska is familiar with timber harvesting, and appreciates the benefits of locally-sourced, sustainable materials to our lifestyle and economy.

Solid wood is also a reasonably good insulator. The thermal properties vary based on the thickness of the panels, but generally provide reasonable performance than can be easily enhanced with a layer of insulation. The panels are also constructed in such a manner that the joints are tighter, which helps improve energy efficiency.

Fire Resistance: The key to safe success.

Many of you have been wondering how CLT would address fire safety. This has been one of the factors that limit wood construction to a few stories in typical buildings. Wood has a great natural protection from fire. As wood burns, it creates a char layer on the outside that prevents heat buildup at the center. This charring effect helps wood retain its strength during a fire. This doesn’t help thin pieces of wood much, since the layer can extend in from all sides on a typical 2×4 stud or I-joist, and penetrate to the core of the material. In CLT design, however, the relatively thick panels can be designed to resist fire by calculating the char rate. Chapter 8 of the CLT handbook goes through the fire performance of CLT, also the 2015 NDS chapter 16 includes requirements to calculate up to a 2-hour structural fire-resistance rating for CLT panels.

I am excited to see how CLT grows over the next 10 years. I have experience designing with CLT and look forward to designing more structures out of it. It is fun, beautiful, and gives us a way of participating in the future.

This summer my family is planning a trip to West Yellowstone and then Whitefish, Montana. We are going to Whitefish to see Glacier National Park. You are probably asking why I mention this… well, Whitefish, Montana has the first 2-story commercial building in the United States that was constructed out of CLT. As a kid, when we went on trips, my father would take us to job sites or would tell us odd facts about buildings, food processing plants, or the road that we were driving on. Well, this time, as the future of the industry changes, it’s my turn to give HIM a bit of knowledge on a building.