Elevated water tanks are essential structures that are a lifelines to the communities they serve. They provide water supply pressure for domestic water and firefighting utility systems. In the aftermath of an earthquake, the continued operation of these structures is critical to the response and recovery of our communities. These unique structures also pose a seismic retrofit challenge due to their size, shape, weight, and the fact that many were designed and constructed decades ago, long before recent advancements in performance-based seismic design standards. Advanced seismic design and retrofit technologies for use in buildings are well-developed, whereas some of these technologies have had limited development and application on non-building structures such as water tanks.

Reid Middleton’s structural engineers grappled with these design problems when two elevated water tanks in the City of Renton were damaged in the 2001 Nisqually Earthquake. We had to determine how post-earthquake structural repairs could be used to provide seismic upgrades to these lifeline structures with minimal cost for maximum earthquake performance benefit. What resulted was an innovative application of performance-based earthquake engineering and seismic damping technologies developed primarily for buildings but adapted to these non-building essential structures.

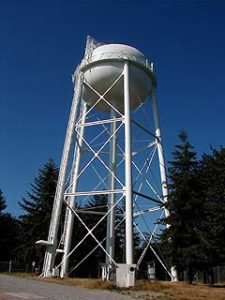

The Elevated Water Tanks

The City of Renton’s two 40- and 50-year-old elevated water tanks supply drinking and fire fighting water to the surrounding community. The 1970s era Rolling Hills Reservoir is 115-feet tall and holds 300,000 gallons. The elevated tank is 45-feet in diameter and 30-feet high. It is supported by a 48-inch-diameter center column and five 36-inch-diameter steel pipe columns. When full, the elevated tank weighs 2.8 million pounds with its center of mass situated approximately 10 stories (100 feet) above the ground. The 1960s era Highlands Reservoir is 135-feet tall and holds 750,000 gallons. The welded steel tank is approximately 67 feet in diameter and 43 feet high. It is supported by a 72-inch-diameter riser column and eight 48-inch-diameter pipe columns. When full, the elevated tank weighs 6.9 million pounds with its center of mass situated approximately 11 stories (115 feet) above the ground.

The magnitude 6.8 Nisqually Earthquake damaged both tanks. On-site observations of the Rolling Hills tank found that the elevated tank swayed for about 20 minutes after the 20-second earthquake. Reid Middleton performed a comprehensive seismic evaluation of each facility and found that the earthquake damage consisted of stretched and buckled steel diagonal braces, stretched and kinked radial rods, and damaged column bases. Significant seismic forces were imparted on these elevated tanks due to their size, shape, and weight.

From Analysis to a Design Solution

This project was very interesting. How can we reduce the tank vibration and swaying while performing minimal structural upgrades to the lateral system? What will the effect of water sloshing on the large tanks have on the seismic loads to the structure? The first step to solving this problem was to create three-dimensional finite element models of each of the elevated tanks. These finite element models were analyzed using earthquake records to determine their structural weaknesses and to analyze various types of seismic upgrade strategies. The most complicated structural analyses were performed on the elevated tanks – nonlinear dynamic time-history analyses with site-specific ground response records. This complex analysis type provides the best understanding of earthquake behavior. Second, a design alternatives analysis and comparison was performed to determine the optimal seismic upgrade repair strategy. The selected seismic upgrade design strategy was extensively modeled with the same nonlinear dynamic analysis procedure to fine tune and optimize the design solution.

Much of the project design borrowed from earthquake engineering technologies initially developed for buildings. Performance-based earthquake engineering design guidelines and standards were used by our design team to enable us to accurately analyze and model the tank structures: design seismic upgrades utilizing innovative friction damper protection device technologies and advanced nonlinear analytical techniques to accurately capture structure performance and to select and optimize our seismic upgrade design solution.

Design Solution Equals Cost Savings

The City needed a seismic repair and retrofit scheme to restore and enhance the capacity of the tank structures to resist earthquake motion, and the solution needed to be cost-effective. It turned out that friction dampers, a technology traditionally used with buildings, provided the optimal seismic upgrade solution for the large and heavy elevated tank structures.

A friction damper consists of a series of plates that are clamped together with high-strength bolts. During an earthquake, the dampers absorb energy and generate heat through the rubbing of the plates much like a person rubbing their hands together generates energy in the form of heat. Just as an automobile’s brakes take energy away from its movement, the dampers control the motion of a vibrating tank structures by absorbing earthquake energy.

By July 2003, the tanks were repaired and their seismic performance upgraded using a series of 60,000- and 70,000-pound friction dampers manufactured by Pall Dynamics. Our design studies determined that using seismic dampers cost 35 percent less than the price of using conventional seismic strengthening methods, which would have required replacing the tank braces with larger steel braces and costly foundation upgrades.

A traditional earthquake repair and seismic retrofit approach would have included replacing the entire bracing structure of the tanks – a very costly endeavor. In fact, subsequent analysis revealed that the costs to retrofit the tanks using conventional strengthening and stiffening methods were about 50 to 80 percent of the cost to replace the tanks.

While water tanks are highly visible structures, they aren’t always what communities think of when performing seismic upgrade needs assessments of their infrastructure. These important facilities need this level of consideration for our communities to be disaster resilient. Government officials and engineers can sometimes be at a loss for how to address the special requirements of these unusually shaped and heavy non-building structures. It turns out that with some innovative engineering and intricate analytical modeling, the seismic retrofitting these non-building structures is not only possible, but it can be done cost-effectively.